New Tires Burlingame

NEW CAR TIRES BURLINGAME CA 94010

Welcome to Shaffer s New Tires near San Mateo where we have the new tires and services you need to help get your vehicle on the road. Schedule an appointment, or come in to Shaffer’s New Tires today.

Let’s first review what new tires are and how they are constructed.

New Tires Technology: The Science & Engineering Behind Making New Tires by:

New tires are one of the most intricate mechanical composites existing in the engineering universe.

The Yokohama Geolander with different layers of the tire showing.

Outside of the rubber and tire world, most people consider tires as simply black and round objects. Makes sense: tires are one of many components on a vehicle and they only seem to come to mind when it’s time to replace them.

However, the science and engineering behind tires is fascinating. It’s complex and unpredictable because tires are one of the most intricate mechanical composites existing in the engineering universe. It’s a clever mix of steel, nylon, polyester and rubber in the form of a round object that’s responsible for most vehicle characteristics. Tires are the true connection of a vehicle to the road, so they need to deliver what’s expected: comfort, safety and reliability. In short, tires carry the vehicle loads at high speed, so they need to be designed with a super-high safety mindset.

Tire development is a combination of art, engineering and science. It’s a never-ending dance with a world of target conflicts, where improving one performance area will affect another one. Tire development engineers work to find the best safe performance balance, delivering desired appearance and assuring the expected cost will be met.

It Starts with Performance

All new tire development starts with performance requirements. Whether engineers design a tire for OEMs (original equipment manufacturers) or the replacement market, a set of requirements will be clearly defined.

In terms of OEM, the new tire’s performance requirements come from the OE manufacturers and it’s set for a specific vehicle or vehicles. But in the replacement tire realm, the performance requirements originate from a product planning team. The team spends most of its time gathering VOC (voice of customers), looking at current product performance, analyzing benchmarking data, reviewing customers’ feedback and press testing data. They crunch the data and create a comprehensive requirement for a new tire line or a specific tire.

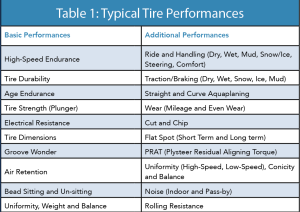

New tire requirements are normally divided into two sets of performances: basic performances and additional performances. As named, basic performances are the characteristics of a tire which need to be met to legally put the tire on the market. Often tire manufacturers put higher basic performance requirements than the legal limits to assure the product will be acceptable in the market over the long run. Basic performances are a combination of legal limits, government requirement (FMVSS, UTQG, etc.) and the internal basic performance expectations from the tire. Additional performances are the characteristics of a tire that differentiate it in the marketplace. Those requirements are often defined by the OEM (in the case of an OE tire) or the product planning team (in the case of a replacement tire).

Table 1 shows typical, basic and additional tire performances which can be used to design a tire. There are other tire performances which may be added on a specific segment or special design (i.e., run-flat tire). There’s a lot we ask from a tire and that’s why tire development is one of the most complex mechanical design elements around. It’s where non-linear behavior of rubber, along with the composite nature of tire (nylon, polyester, steel, rubber) have to deliver every single performance required to safely fit on the vehicle.

Typical Tire Performance Characteristics

New Tires Development Steps

Expectations from tire engineers during tire development are extremely high. This puts a lot of pressure on engineers, but they are not alone. Tire manufacturers spend millions of dollars annually on research and development (R&D) to provide practical prediction tools, state-of-the-art material, new ways of tire production, plus comprehensive know-how and design catalogs for development engineers to use. These tools help development engineers to design the best possible tire for the market. They are able to model every element(s) of the tire on their supercomputers and predict the performance before investing any money on tooling.

After they are confident the optimum design has been achieved and it delivers the performance requirements, tire engineers will order experimental molds. Then they’ll build tires and test them in real conditions to assure the actual performances meet the requirements and are in line with the prediction tool’s results. Tire engineers, along with testing engineers, will test all specifications to assure the tire will meet the requirements. In a typical development cycle, the design of a new OE tire can take between 14 and 36 months. The design of a new product line for the replacement market can take between 18 and 24 months. Engineers normally need two or three loops of designs before they are able to achieve all the performance requirements.

Tire Design Elements

In order to achieve complex performance requirements, engineers have four distinct elements to work with. These elements, along with the interaction between them, will define overall tire performance. The four elements are:

1. Tire Tread Pattern

2. Tire Contour

3. Tire Construction

4. Tire Compounds

New Tire Design Sequences

Development engineers often start by creating a tread pattern, as customers normally define appearance requirements for the specific tire. Based on the category of the tire and the segmentation of the product, the base pattern will be selected. The base pattern can be an existing pattern, one from a pattern library or a completely new design based on styling requirements and/or inspired from a competitor’s appearance.

After designing the tread pattern, development engineers design the tire contour. Based on the designs of the tread pattern and tire contour, they will complete mold drawings and order the mold.

In parallel to the creation of mold drawings, development engineers will work to find the best tread compound and assemble the tire construction to achieve the remaining performance.

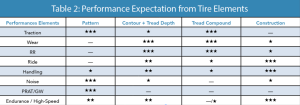

Table 2 below shows how tire engineers normally attack the performance requirement based on the four tire elements for design.

The following explains the details of designing each tire element and the expected performances.

Performance Expectations from Tire Elements

Table 2: Performance Expectations from Tire Elements

New Tire Tread Pattern

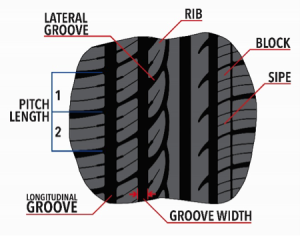

While the tread pattern contributes to almost all tire performances, tire engineers normally design the pattern to achieve the targeted tractions (wet, dry, snow), groove wonder (GW), PRAT and noise. The balance between siping, void ratio, block stiffness, groove size, groove positions and tread depth will be what is needed to achieve required performances.

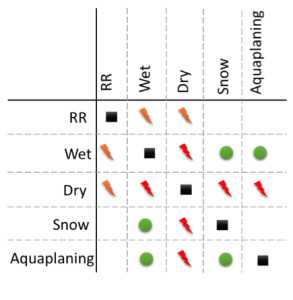

Sipe designs mainly contribute to achieving snow performance. Increasing sipe density will improve the snow performance of the tire, yet will be in direct conflict with dry performance. Groove size and void ratio are factors that influence wet performance, and block stiffness determines dry performance. Wider rib sizes and increased void ratio will result in a better wet performance but may decrease dry performance. A stiffer block will improve dry braking, but will cause degradation in snow performance. The groove position is designed to meet the groove wonder requirements and the tread block angles are set to achieve the PRAT requirements for the tire.

PRAT, in simple words, is the ability of the car to stay on the road without any steering input. The groove wonder is the ability of the car to move in road grooves without the generation of excessive noise or handling disruptions. Tread depth will always be the balance between rolling resistance, tire cost and wear. Of course, each segment has its own expectation of the minimum tread depth, which would be the criteria when engineers originally design the tread pattern.

Pitch length, pitch sequence and pattern see through (PST) will be optimized to achieve targeted noise performance and deliver the best wet vs. noise trade-off.

Figure 2 shows a pattern design element to develop an optimized pattern. Figure 3 shows typical trade-offs on performance during pattern design.

Within a tire company, there are several prediction tools available to provide an optimum block, void, groove concept for the tire and enable engineers to estimate snow, wet, dry, GW, PRAT and noise performance. While the tools will never be able to predict the complexity of road conditions, they can provide a very good base for engineers when designing their first experimental tire.

new tire tread pattern design

Figure 2: New Tire Tread Pattern Design

New tire development goals and tire pattern development

Figure 3: Typical development goals often compete and conflict for pattern development

Tire Contour

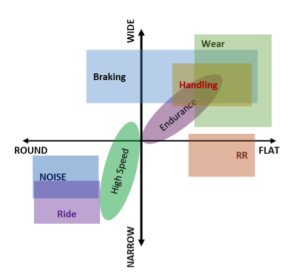

In simple terms, tire contour provides the shape of the tire and how round/flat or wide/narrow it can be designed. It also provides the foundation of the tire footprint. Although the tire footprint can be slightly modified by a different construction design, it’s mainly influenced by tire contour.

The main task for development engineers is to provide an optimum footprint to achieve the best tire handling and even tire pressure distribution for the greatest wear performance and fuel efficiency. In general, a flatter tire contour provides better wear and handling performance but has a trade-off on ride and noise. At the same time, a rounder tire contour design provides a better ride and noise performance, and often better high-speed capability, while compromising handling, wear and braking.

In general, a wider tire may be better for wear and handling, but it will increase the total cost of the tire and rolling resistance (RR). It may also be more difficult to be manufacture.

It’s up to tire development engineers to find an optimum balance between how wide/flat, narrow/round a tire can be designed.

Figure 4 shows the typical trade-off on tire performance by a different contour design.

Tire development engineers use FEM (finite element modeling) to predict an optimum tire contour fitting for the required performances on wear, rolling resistance, ride and handling, while maintaining other performances.

Tire contour development engineering

Figure 4: Typical development goals and conflicts for tire contour development

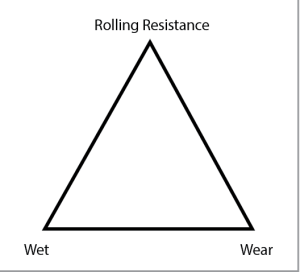

While every compound in tires is important, the most talked about is the tread compound. It’s one of the most important compounds in the tire because it provides the connection to the road. Expectations from the tread compound are super high. Each tread is generally divided into three compounds: tread cap(s), tread base and tread wings/sides. In some cases, the tire tread cap contains two different compounds placed horizontally/vertically (depending on the performance expectations) to each other. While the majority of performances are affected by tread compounds, engineers focus on wear, wet, RR, dry, cut-and-chip resistance, vehicle ride and handling while developing the tread compound.

Like other tire components, trade-off and optimization are the name of the game. The magic triangle of wet, wear and rolling resistance is what compound engineers always try to expand. It’s where improvement of one will reduce the other two performances (Figure 5). Developing a bigger triangle is the focus on compound development. In most cases, tire engineers use the tread compound library and select the compounds which will deliver the closest performance to the requirement engineering optimal tire performance Figure 5: The optimal tire performance triangle

Tire Construction

Tire construction is the final element for engineers to use and achieve the last remaining performances.

Like the tread compound, construction plays an important role on all performances. However, engineers focus on the construction in order to achieve the basic performance expectations and provide the best balance between ride and handling, while maintaining the rolling resistance requirement.

Tire construction also has an important role on the tire flat spot. The combination of ply and cap-ply type, along with the design, should be considered to assure the tire will have the least flat spot in the short- and long-term on the vehicle.

Experimental New Tire Building

Now that all the components are designed, the tire engineer will prepare the mold/tool drawings, check and make sure the prediction tools will deliver what’s expected and order the mold/tooling.

The mold usually has the longest lead time and should be ordered quickly to achieve the project timing. For that development, engineers often help the drafting department to complete the mold drawings and order the mold.

In most cases, factories are already equipped with the tooling (building, curing, etc.) to build the tire; however, some factories may require ordering additional tooling when a new tire size or design will be introduced.

Upon mold delivery, tire engineers put several specifications together. Specifications are reviewed by the experimental production team, the tires are built, inspections will be done, and they are ready for shipment.

Experimental Tire Testing

After the tire is released by the experimental production team, it will be then shipped to a testing facility for indoor and outdoor testing. Indoor testing does not require vehicles and is often done on machines. Outdoor testing does require vehicles and is often done on a track.

Tire engineers issue a test order for the program and the test engineers conduct all the required testing and provide the performance results. Engineers review the test data and compare those with the performance requirements and the prediction tools outcome. Depending on the data, engineers may release the tire into production, send it back to the white board to modify the design or decide to continue with additional builds/modifications.

In most cases, the expectation of performance from the tread pattern and tire contour has been met on first loop and the engineers spend the next couple of loops adjusting the compounds and constructions in order to achieve the overall performance.

Initial and Mass Production

Once overall performance is achieved, the tire engineers will order production tooling, finalize legal certifications and prepare the tire for mass production.

The production team – with an assist from the tire engineers – will introduce the tire to production and continue monitoring it until production is stable and the tire can be staged to mass production.

At that point, the new tires are fully released to mass production and will continue to be built based on customer orders.

Product Monitoring

With help from the product planning and technical service team, tire engineers will continue to monitor the tire in the market and review feedback to assure its performance is in line with expectations. This information will be used to further improve the tire (product facelift) and as “lessons learned” for future tire developments.

The Science Behind Tire Price

A question everyone asks is if the tire engineers follow the same procedures, why is there so much variability between tire prices in the market? Why is there a price difference of $10 to $50 per for new tires within a specific segment from different tire manufacturers?

Defining tire price is a market-based practice. It all depends on product positioning, expected margin from the product, brand perception and ultimately, tire cost as the biggest factor.

Tire cost is always based on performance expectations, cost of production, material costs and purchasing practice, factory of origin and logistic costs. While performance expectation is one of the biggest influences to determine tire cost, other factors also play an important role in regards to the difference on tire cost/price within the same segment.

For example, in the high-performance segment, company “A” can focus on delivering the best overall wet performer in market, while the remaining performances will be in line to the competitors. In this case, company “A” may highlight the usage of a high silica content tread compound. While this will improve tire performance in wet conditions, it will also significantly increase the overall tire cost. In the exact same segment, company “B” may decide to have an acceptable overall performance for the tire. As a result, they may use low/no content silica in the tread compound of the tire. The upshot of the two completely different approaches to the same segment is why that the cost/price gap between company “A” and company “B” will be significant.

The challenge is most of those performance leaps may not be seen by the normal customer on his/her daily drive, but company “A” will count on editorial, enthusiastic crowds and influential people to drive the product, notice the differences and communicate it with end users, which eventually will drive sales to company “A.”

This kind of approach puts the product in a winning position in media testing and recommendations lists which will also increase company “A’s” sales.

In another example, company “C” decides to deliver the best overall performance at a much higher wear performance and include the highest product warranty in the market. In this case, company “C” will use a deeper tread depth, a wider/flatter contour with state-of-the-art carbon black and sulfur content in the tire to achieve the highest wear performance level, while maintaining other performances. In the same segment, company “D” may decide to deliver mid-tier wear performance with acceptable other performances. As a result, company “C” will deliver a much better product at a higher price than company “D.”

The factory’s overall overhead, volume of tire production, SKU complexity within the factory and tooling age are other parameters that drive the overall tire cost. In most cases, newer tooling may cost higher and will deliver better uniformity and balance for the end consumer, but will drive the cost of production higher.

Logistics costs and the way dealers purchase tires are other areas that create a price/cost difference in the market.

And, of course, margin expectation and the brand’s positioning will affect the tire price versus competitors.

All and all, these are the reasons for finding such a wide variety of new tires prices in the market. Defining the overall tire price is combination of art, science and accounting, and comes directly from the end consumer’s product performance expectation and brand perception.

Summary

By now, you probably agree that a new tires are not simply a round and black object and that there are years of engineering work with millions of R&D dollars invested into what goes behind the development of a tire.

Shaffer’s Tire

1309 N. Carolan Ave

Burlingame, CA 94010

DIRECTIONS

Mon-Fri:8:30am-5:30pm

650-344-0302

© 2020 Shaffer’s Tires All Right Reserved